A 16k line scan camera offers several reasons that make it of high significance for imaging applications of all kinds in almost all types of industries. It boasts an exceptional resolution: 16,384 pixels per line. At such a high number of pixels, there are minute details necessary to industries such as semiconductor manufacturing wherein a small defect can lead to poor quality products. For example, with a 16k line scan camera, there can be a point of view that defect detection rates may increase up to 30% compared to lower resolution models.

Other important characteristics include increased dynamic range: many line scan cameras now achieve 70 dB, thus being able to capture dark and bright areas within one image without losing details. This is greatly appreciated in applications such as food packaging inspection, where different shades of color may mean spoilage or contamination. As said by industry analyst Sarah Johnson, "The ability to see subtle color differences can make the difference between a salable product and waste.".

Another major advantage of camera speed is that most 16k line scan cameras have line rates over 40 kHz, thus enabling the cameras to follow fast production lines. For example, in textile production, this enables one to inspect at speeds over 200 meters per minute without slowing the production line and hence maintaining constant quality control. As indicated in a recent study, companies that incorporated the high-speed line scan cameras increased their throughput by 25%.

In addition, 16k line scan cameras utilize multiple algorithms that enhance feature detection and classification. Many of these can improve object recognition accuracy by up to 20%, thereby allowing applications such as automated sorting and packaging. Then, in electronics manufacturing, accurate placement of components can improve assembly line efficiency since errors are typically diminished.

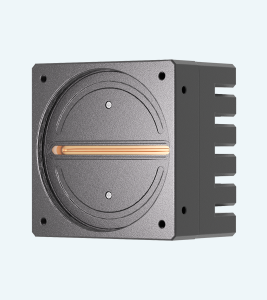

Moreover, such cameras must be integration-capable. Most of the 16k line scan cameras come with standard interfaces, such as Camera Link and GigE Vision. It will be integrated very smoothly into your existing system. It will even save you a lot of hassle when setting them up and the new infrastructures.

Another area that shines particularly is the strength of 16k line scan cameras. Built to withstand difficult environments, several models are ruggedized with IP67 ratings to withstand dust and moisture. In most manufacturing settings, loss of equipment can be severely impactful in terms of downtime. "Investing in rugged equipment pays off in less maintenance and longer operational lifetimes," says Mark Williams, expert engineer.

A 16k line scan camera would primarily add better imagery in most applications, ensure that the images are of high quality, and streamline production output times. High-end technology often only improves the detection of flaws but provides the ability to have faster processing rates, which makes it an invaluable asset for modern manufacturing operations.